As part of our zero waste ethos at David Blume’s Whiskey Hill Farms & Science Center, we use two fermentation processes to produce alcohol and fertilizer. Instead of the current practice of treating most agricultural byproduct from agricultural operations as waste, this process turns this “waste” biomass into fertilizer and alcohol and reduces the waste stream going to the county landfill.

The Process of Double Fermentation to Produce Alcohol, Fertilizer & More

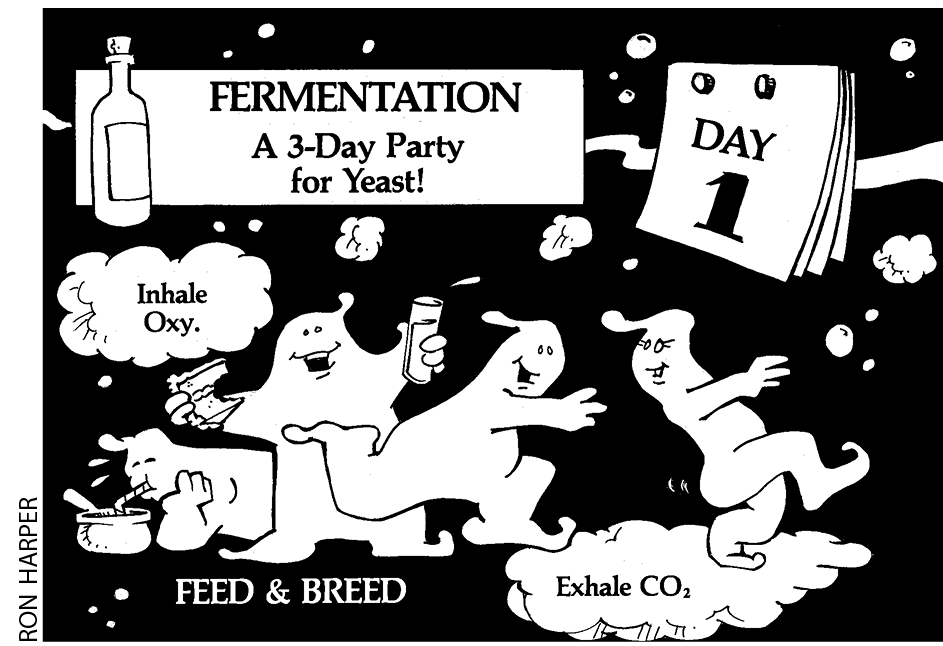

First fermentation: The plant material is first subjected to yeast fermentation (the same process that is required for production of wine by a winery operation). This initial fermentation produces CO2 gas, which is used in the on-site green houses to spur plant growth, and which results in a liquid and a solid component. The liquid component is distilled, producing alcohol. The solid components are used to produce fertilizer (nine gallons for every gallon of alcohol) in the second fermentation, below.

The following types of alcohol can be produced simply by employing different types of filtration during the finishing process:

- Fuel grade alcohol

- Beverage grade alcohol

- Medical grade alcohol

- Pharmaceutical grade alcohol

Second fermentation: Following this initial alcohol distillation process, the remaining solids are fermented again using bacteria, rather than yeast. This bacterial fermentation produces methane (renewable natural gas) and liquid fertilizer. The methane can be used to fuel the on-site boiler, and the fertilizer can be applied to the crops produced by Whiskey Hill Farms and delivered to other agricultural operations in the area. For every nine gallons of fertilizer produced, a gallon of alcohol as a by-product is distilled.

The Benefits of Our Double Fermentation Process

The production of plant-based, non-petroleum organic fertilizer can supply on-site needs as well as the needs of other local agricultural operations, and also provides for efficient disposal and use of agricultural wastes from both on- and off-site agricultural operations.

Medical grade alcohol is the key ingredient for disinfection products. Cannabis manufacturers also use the highly purified alcohol for use in the extraction process. Alcohol-based sanitizers are required to be used in many facets of agricultural operations to prevent contamination and to ensure consumer safety. These requirements have been promulgated by the Food Safety Modernization Act (a more detailed description of these requirements is attached).

Another option is fuel grade alcohol production. Whiskey Hill Farms has had discussions with the City of Watsonville regarding producing alcohol to power their fleet, and with the Pajaro Valley Unified School District (PVUSD)about fueling their buses to comply with the state-mandated phase-out of the use of diesel fuel due to its extreme toxicity.